Excellence in the dry granulation manufacturing process

Excellence in the dry granulation manufacturing process

PharmaDGTech, short for Pharmaceutical Dry Granulation Technology, emerged in late 2020 with a singular vision: to revolutionize and streamline dry production processes through the utilization of AGS (Aerodynamic Granulation System) patented technology.

Innovative DGES (Dry Granulation Enhanced System)

This pioneering system, uniquely tailored for continuous operation, epitomizes our commitment to delivering uniform, dust-free granules with exceptional flow characteristics and enhanced properties for drug product formulation.

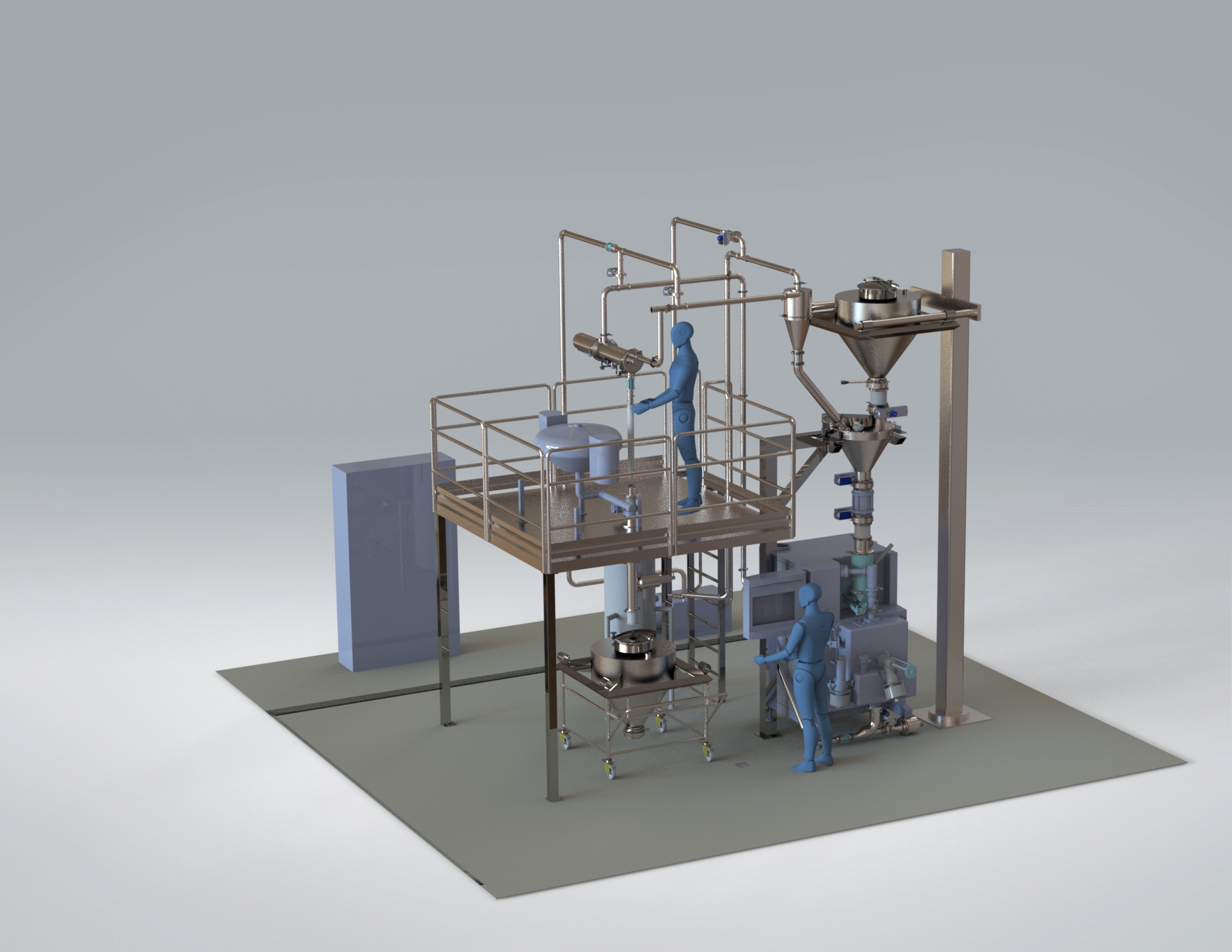

At the heart of our innovative DGES (Dry Granulation Enhanced System) lies the AGS technology (Aerodynamic Granulation System) which is meticulously conceptualized to function seamlessly under continuous airflow or inert gas, ensuring consistent and verifiable outcomes. Versatile in its application, the DGES demonstrates unparalleled efficacy in processing a wide spectrum of pharmaceutical and nutraceutical powders (both pure drug substances/raw materials or blends), surpassing the capabilities of conventional compacting methods.

Innovative DGES (Dry Granulation Enhanced System)

This pioneering system, uniquely tailored for continuous operation, epitomizes our commitment to delivering uniform, dust-free granules with exceptional flow characteristics and enhanced properties for drug product formulation.

At the heart of our innovative DGES (Dry Granulation Enhanced System) lies the AGS technology (Aerodynamic Granulation System) which is meticulously conceptualized to function seamlessly under continuous airflow or inert gas, ensuring consistent and verifiable outcomes. Versatile in its application, the DGES demonstrates unparalleled efficacy in processing a wide spectrum of pharmaceutical and nutraceutical powders (both pure drug substances/raw materials or blends), surpassing the capabilities of conventional compacting methods.

Shaping the future of granulation technology

Our dedication extends beyond product development to optimizing each component of our equipment. Leveraging advanced automation technologies, we monitor in real-time and refine operations parameters, fostering continuous improvement and scientific advancement. Through rigorous comparative analyses, we gain invaluable insights into particle quality under airflow, paving the way for potential breakthroughs and patents across pharmaceutical, chemical, and nutraceutical sectors.

At PharmaDGTech, we are not merely innovators; we are pioneers in shaping the future of granulation technology. With an unwavering commitment to excellence and a passion for discovery of new ways, we strive to empower our clients with cutting-edge solutions that redefine industry standards and drive transformative progress.

Our Main Service

We are active in the field of dry, room-temperature, closed-circuit granulation, which can be applied to raw materials for the pharmaceutical, nutraceutical, food and cosmetic industries.

Our Vision

We have the ambition to innovate the granulation processes of active ingredients and excipients in the chemical-pharmaceutical, nutraceutical, food and cosmetic sectors.

Our Mission

We are committed via this innovative technology to deliver greater process efficiency, increased safety of operations, sustainability and better control of the quality of the granules.

Contact Us

Do you have any questions for us? We can help you!

Contact us, our advisors can help you with your questions.

Subscribe To Our Newsletter

Stay in touch with us to get latest news and special offers.